As the global demand for aesthetic and invisible orthodontic treatment continues to rise, the future of clear aligner design and manufacturing is being redefined by artificial intelligence (AI). The integration of AI-driven automation, robotics, and intelligent software is ushering in a new era of speed, precision, and scalability in orthodontic production.

At the forefront of this transformation is the HyperBrain Orthodontic Robot-Based Aligner Cutting System—a breakthrough innovation that seamlessly merges intelligent algorithms with industrial-grade robotics to deliver unparalleled efficiency and accuracy in clear aligner production.

The Rising Demand for Aesthetic Orthodontic Solutions

Aesthetic medicine has seen a major boom in recent years, driven by a growing preference for minimally invasive procedures and personalized cosmetic outcomes. Clear aligners, which offer discreet and comfortable teeth correction, have become a cornerstone of this trend.

However, behind every set of invisible aligners lies a complex production process that demands exceptional precision—from digital design and thermoforming to trimming and finishing. Traditional manufacturing setups often rely heavily on manual work, which can limit productivity and consistency.

To address these challenges, ConverSight’s HyperBrain Orthodontic System introduces a new benchmark for AI-assisted invisible orthodontics equipment manufacturing, enabling the industry to scale faster and smarter than ever before.

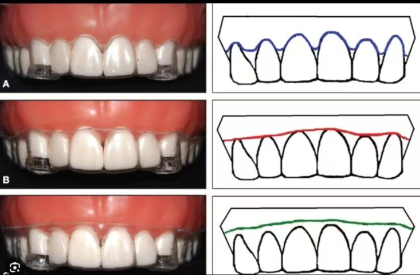

Batch Gingival Line Extraction: Speed Meets Precision

One of the most time-consuming steps in clear aligner production is extracting gingival lines and creating precise cutting trajectories for each dental model. Conventional software often struggles with batch data processing or maintaining accuracy across complex dental geometries.

The HyperBrain system revolutionizes this stage with its AI-based gingival line extraction feature. Leveraging advanced vision recognition and dental anatomy algorithms, the system can automatically identify gingival margins in batches, quickly generating accurate cutting lines that align with the patient’s digital treatment plan.

This not only minimizes human error but also ensures uniform precision across large-scale production. Manufacturers can now process hundreds of aligner models simultaneously—turning what once took hours into a matter of minutes.

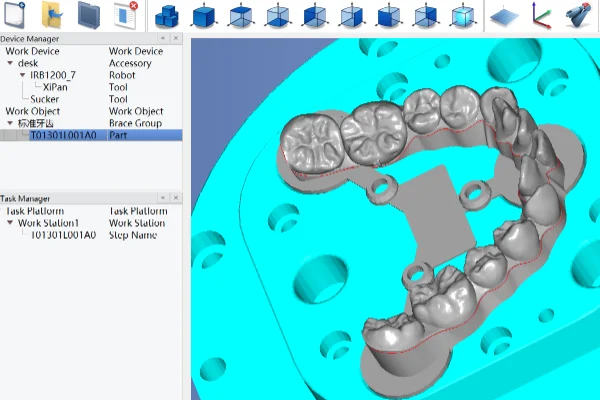

Intelligent Cutting Trajectory Generation

Once the gingival line is extracted, the next critical step is determining the exact cutting path for the aligner edges. This trajectory must perfectly match the tooth model’s contour to guarantee comfort and fit.

HyperBrain’s smart trajectory generation engine automates this process entirely. By analyzing the digital model in 3D, the software computes an optimal trimming path that ensures smooth edges and consistent thickness.

Whether dealing with regular teeth alignment cases or more complex orthodontic geometries, the system maintains high stability and repeatability. This capability forms the foundation for achieving flexible yet standardized aligner trimming—a key advantage for large-scale manufacturers.

Advanced AI Robotic Control for Smart Operations

The heart of the HyperBrain system lies in its AI robotic control algorithm, designed to transform complex production tasks into fully automated workflows. The software automatically generates robot operation codes that guide the robotic arm’s movements during trimming and finishing.

Using ICP (Iterative Closest Point) algorithms, the system acquires high-precision surface data from each aligner model. It then computes the exact position for robotic cutting and even laser marking—ensuring every step aligns with the digital design file.

This millimeter-level precision enables the robot to adapt dynamically to shape variations, maintaining consistency across thousands of units. The result is a streamlined, error-free operation that dramatically reduces manual intervention while enhancing quality assurance.

Data-Driven Manufacturing for Consistent Results

What sets the HyperBrain platform apart is its ability to learn and improve continuously. Each production cycle feeds data back into the system, allowing AI algorithms to refine their performance and optimize cutting accuracy.

Through this self-learning mechanism, manufacturers benefit from progressive quality enhancement—aligners become more precise over time, with fewer adjustments and less material waste. The software’s integrated database of material behavior also ensures that temperature, pressure, and trimming speed are automatically adjusted to suit different film types.

This fusion of machine learning and process intelligence turns orthodontic production from an experience-driven craft into a data-driven science.

Rapid Market Adaptation Through Software Innovation

In a rapidly evolving industry, the ability to respond to new materials, clinical standards, and aesthetic preferences is vital. ConverSight technical team continuously updates the HyperBrain algorithm packages to meet emerging demands.

For example, when users reported challenges with complex dental models, the system was upgraded with a denser 3D scanning grid and improved contour detection. The result was a significant boost in fit precision and molding accuracy—demonstrating how AI-driven adaptability can sustain competitive advantage.

Such responsiveness allows manufacturers to keep pace with innovation and maintain their leadership in an increasingly crowded clear aligner market.

Global Market Leadership and Industrial Standards

With its proprietary software and robotic automation,HyperBrain system now commands about 80% of the domestic market share in clear aligner cutting solutions. Its success has extended beyond national borders, as the system gains traction across global markets known for stringent quality and aesthetic standards.

This dominance is rooted in the company’s commitment to precision, reliability, and compliance with international dental aesthetic medicine norms. Every equipment is designed to help orthodontic manufacturers meet or exceed these standards—ensuring that patients worldwide enjoy perfectly fitting, comfortable aligners.

Transforming the Future of Clear Aligner Production

The integration of AI into orthodontic manufacturing is more than a technological leap—it’s a paradigm shift. With intelligent systems like HyperBrain, dental labs and aligner brands can now move from manual-dependent workflows to fully automatic production ecosystems.

This transformation delivers tangible benefits:

Shorter development cycles, as AI-driven algorithms accelerate parameter optimization.

Higher production throughput, thanks to batch processing and 24/7 robotic operation.

Improved consistency and patient comfort, as smart control ensures precision for processing of every aligner.

Scalable manufacturing, where increasing output no longer means compromising quality.

Ultimately, AI-driven automation is not replacing human expertise—it’s amplifying it. By removing repetitive and error-prone tasks, engineers and clinicians can focus on innovation, customization, and improving patient experiences.

Conclusion: The Future is Clear, Intelligent, and Automated

The rise of AI in clear aligner production marks a turning point for the dental industry. As digital dentistry and aesthetic medicine continue to converge, intelligent systems like the HyperBrain Orthodontic Robot-Based Aligner Cutting System will define the next chapter of innovation.

By combining robotic precision, intelligent data processing, and adaptive software algorithms, ConverSight is helping orthodontic manufacturers not only keeping up with the market needs—but shaping its future.

The age of AI-driven clear aligner production has arrived—and it’s transforming smiles with every intelligent cut.

www.conversighttech.com

ConverSight Technology Limited

About Author

You may also like

-

A Practical Guide to Industrial Plane Locks: How to Select the Right Plane Lock for Cabinets and Equipment

-

Benefits of Using Industrial Hardfacing Welding Machines in Mining Applications

-

Coriolis Mass Flow Meters with High Accuracy for Viscous Fluids

-

The Advantages of Using Three-Phase Asynchronous Motors in Manufacturing

-

Why Engineers Choose the J30J Series Rectangular Connector for Their Designs