In the world of motion sensing and navigation, six-axis MEMS IMUs have become indispensable components across industries ranging from robotics to automotive to consumer electronics. But what exactly are these devices, how do they work, and when should engineers and designers choose them over alternative sensor solutions? Let’s dive in.

What Is a Six-Axis MEMS IMU?

A six-axis MEMS IMU (Inertial Measurement Unit) is a compact inertial sensor that integrates six degrees of freedom by combining:

-

A three-axis accelerometer (measuring linear acceleration along X, Y, and Z axes), and

-

A three-axis gyroscope (measuring angular rate or rotation around those same axes).

This combination enables the device to sense both motion and orientation dynamics in space. Because it’s implemented using MEMS (Micro-Electro-Mechanical Systems) technology, these IMUs are small, low-power, and cost-effective compared to larger or more complex inertial systems.

Unlike nine-axis IMUs (which also include a magnetometer), six-axis units focus solely on acceleration and rotation data — perfect for systems where magnetic field compensation is unnecessary or might even introduce distortions.

To explore real six-axis MEMS IMU products and technical specifications, check out LINS’s MEMS IMU offerings here: https://www.lins-imu.com/MEMS-IMU.

How Do Six-Axis IMUs Work?

At their core, six-axis IMUs harness tiny mechanical structures etched on silicon chips. These structures flex or twist with motion, creating electrical signals that correspond to motion along or around each axis. Sophisticated onboard or external signal processing then translates these raw measurements into usable data for your system’s navigation, control, or data-logging needs.

Key Advantages of Six-Axis MEMS IMUs

Here’s why six-axis MEMS IMUs are popular in embedded systems and motion-critical applications:

Compact & Low-Power

Their microelectromechanical design keeps size and energy requirements down — perfect for drones, robotics, wearables, and more.

Fast Dynamic Response

Without additional sensors like magnetometers, data from gyros and accel sensors is available with lower latency, ideal for real-time control loops and rapid motion environments.

Cost-Effective

Fewer components and simpler integration typically translate to lower system cost compared to multi-sensor IMUs.

Robust Performance

Many industrial MEMS IMUs, such as those offered by LINS, are engineered for temperature stability, shock tolerance, and low bias drift, making them reliable in demanding conditions.

When Should You Use a Six-Axis MEMS IMU?

Six-axis MEMS IMUs are well-suited for systems that need accurate motion and orientation sensing but do not necessarily require full absolute heading (magnetic) data. Typical use cases include:

Robotics & Autonomous Systems

For attitude control, balance, and motion feedback — drones, ground robots, and industrial bots rely on six-axis sensing for stability and path tracking.

Wearables & Human Motion Tracking

Low power and compact size make them ideal for smart wearables and activity sensors.

Automotive & Vehicle Dynamics

Useful in systems like tilt detection, rollover sensing, and basic dead-reckoning (when GPS might be weak or unavailable).

Industrial Monitoring

Applications like vibration analysis or platform stabilization often leverage six-axis data for real-time feedback.

Navigation in GPS-Denied Environments

As part of larger inertial navigation schemes or tight sensor fusion architectures, they offer essential motion cues.

Choosing the Right MEMS IMU from LINS

If you’re considering a six-axis IMU for your next project, LINS Technology offers a range of products tailored to performance and robustness needs. For example:

-

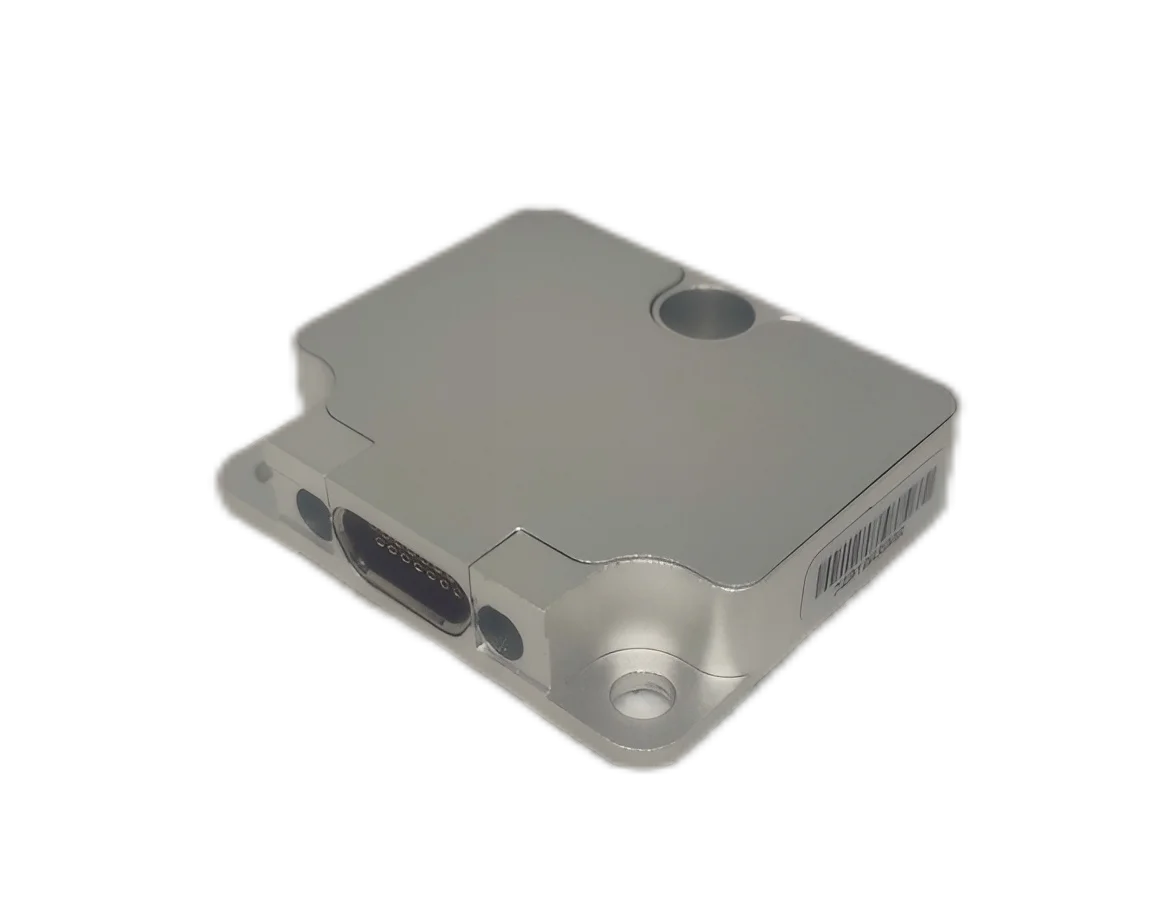

The LINS630 is a high-precision IMU with strong environmental resistance and low bias instability — suitable for intelligent driving, UAVs, and AGVs.

-

The LINS354 industrial solution balances durability and cost for ground vehicles and marine platforms.

-

The LINS800 pairs high dynamic range with advanced calibration techniques for demanding autonomous systems.

Explore the full product lineup here: https://www.lins-imu.com/MEMS-IMU.

Conclusion

Six-axis MEMS IMUs are powerful, compact, and cost-efficient tools for measuring motion and orientation across many embedded systems. Whether you’re building a self-balancing robot, an autonomous drone, or a wearable motion tracker, six-axis IMUs deliver essential motion information with low latency and strong reliability.

With advancing MEMS technology and offerings from manufacturers like LINS Technology, integrating these sensors into modern systems has never been more accessible. Check out their product range to find the right IMU for your application.

Common Questions (FAQ)

Q: What’s the difference between six-axis and nine-axis IMUs?

A: Six-axis IMUs measure acceleration and rotation (via accelerometers and gyros). Nine-axis IMUs add a magnetometer to also sense Earth's magnetic field, enabling absolute heading estimation. Six-axis is simpler and lower power, while nine-axis offers more complete orientation data.

Q: Can six-axis IMUs be used for full navigation?

A: They can form part of a navigation solution, especially when fused with GPS, vision, or other sensors, but alone they won’t provide absolute heading or long-term drift correction.

Q: Are six-axis IMUs suitable for high-speed applications?

A: Yes — many MEMS IMUs are designed with extended dynamic ranges and fast response times, making them suitable for rapid motion and vibration monitoring.

Q: How do I choose the right IMU model for my project?

A: Consider your application’s required range (acceleration and rotation), environmental conditions (temperature, shock), interface needs (SPI, CAN, etc.), size, and power budget. Engineering datasheets and supplier support can greatly help selection.

Integrating MEMS IMUs into Robotics and UAV Systems: Best Practices

www.lins-imu.com

Wuxi LINS Technology Co., Ltd.

About Author

You may also like

-

A Practical Guide to Industrial Plane Locks: How to Select the Right Plane Lock for Cabinets and Equipment

-

Benefits of Using Industrial Hardfacing Welding Machines in Mining Applications

-

Coriolis Mass Flow Meters with High Accuracy for Viscous Fluids

-

The Advantages of Using Three-Phase Asynchronous Motors in Manufacturing

-

Why Engineers Choose the J30J Series Rectangular Connector for Their Designs