In today’s industrial landscape, effective wastewater treatment and air purification are no longer optional—they’re critical. Biological filtration has become a widely adopted method across industries due to its ability to naturally and efficiently remove organic pollutants from water and air. At the heart of every successful biofiltration system lies a crucial component: biological filter materials.

Whether you're managing an industrial wastewater facility, aquaculture system, landfill leachate plant, or odor treatment unit, selecting the right filter media can make or break your system's efficiency and long-term performance.

In this article, we’ll explore the key features to look for in biological filter materials for industrial use, and how Feierda, a leading innovator in eco-friendly filtration solutions, is helping industries around the world meet increasingly strict environmental standards.

What Are Biological Filter Materials?

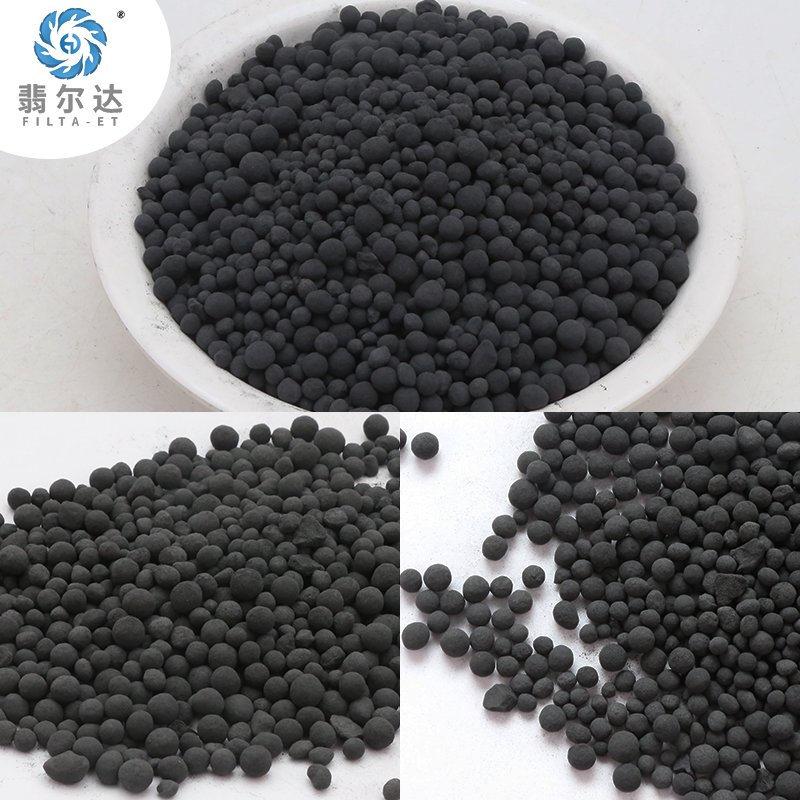

Biological filter materials—also known as bio-media—are specially engineered materials used in biological filtration systems to support the growth of microorganisms that degrade contaminants. These filter materials act as a habitat for beneficial bacteria that metabolize organic compounds, nitrogen, sulfides, and other pollutants.

They’re commonly used in:

Industrial wastewater treatment

Odor control systems

Aquaculture and fish farming

Leachate treatment

Air biofiltration units

Key Features to Look for in Industrial Biological Filter Materials

When choosing filter media for industrial use, it’s essential to consider performance, durability, and long-term efficiency. Below are the critical factors:

1. High Specific Surface Area

A larger surface area allows for more microbial attachment, leading to higher biological activity and faster pollutant breakdown. Premium filter materials are designed with intricate shapes (e.g., honeycomb, multi-layer, or porous structures) to maximize surface area while maintaining optimal flow.

Feierda develops bio-filter media with extremely high surface area-to-volume ratios, which greatly enhance microbial colonization and biodegradation efficiency.

2. Excellent Air and Water Permeability

Efficient oxygen and water flow are critical for aerobic microbial processes. Materials should be engineered to minimize clogging while allowing sufficient movement of fluids or gases through the media.

Feierda's filter materials feature open-cell designs and engineered porosity that ensure consistent permeability, even under high flow or high-loading conditions.

3. Strong Mechanical Strength and Chemical Resistance

Industrial systems often operate under harsh conditions, with fluctuating temperatures, chemical exposure, and heavy loads. Biological filter media must withstand these stresses without deforming or degrading.

Feierda uses advanced polymer materials and proprietary production techniques to manufacture filter media that resist corrosion, high temperatures, and chemical attack, ensuring longevity and stability.

4. Hydrophilicity and Biocompatibility

To support bacterial growth, filter materials should be water-retentive and biocompatible. Hydrophilic surfaces allow bacteria to adhere and form biofilms more effectively.

Feierda’s media are specially treated to increase surface wettability, making them ideal for both aerobic and anaerobic biological treatment systems.

5. Low Density and Easy Installation

In large-scale systems, ease of installation and maintenance is key. Lightweight filter media reduce structural load, lower transportation costs, and make setup easier.

Feierda offers modular and easy-to-handle bio media solutions, available in a range of shapes and densities for different system configurations.

6. Eco-Friendly and Recyclable

As environmental responsibility becomes a growing concern, the sustainability of filtration media is also important. Biological filter materials should be non-toxic, recyclable, and environmentally safe.

Feierda takes sustainability seriously, using recyclable polymers and green manufacturing processes to ensure that their products meet global environmental standards.

Applications of Feierda’s Biological Filter Materials

Feierda’s product portfolio supports a wide range of industrial and municipal applications:

Municipal and industrial wastewater treatment

Odor removal in sewage plants and composting sites

Ammonia and nitrogen removal in aquaculture

VOC control in air filtration systems

Leachate bio-treatment in landfills

With custom engineering support, Feierda also designs tailor-made solutions for specialized needs in energy, food processing, and chemical industries.

Why Choose Feierda?

With years of experience and a deep commitment to R&D, Feierda stands at the forefront of biological filter material innovation. Here’s why industries trust Feierda:

Advanced R&D Capability: In-house labs and testing facilities

Modern Manufacturing: Scalable, high-precision production systems

Eco-Focused: Environmentally responsible materials and practices

Custom Solutions: Tailored media design for diverse industrial needs

Global Supply: Reliable delivery and technical support worldwide

Conclusion

Choosing the right biological filter materials for industrial use is essential for effective, sustainable, and low-maintenance filtration systems. From high surface area to chemical resistance and environmental compliance, every feature plays a role in long-term success.

As a trusted name in the field, Feierda delivers cutting-edge, eco-friendly filter materials designed to meet the evolving demands of modern industry.

How Biological Filter Media Improve Wastewater Treatment Efficiency

www.filta-et.net

Feierda Environmental Technology (Zhenjiang) Co., Ltd.

About Author

You may also like

-

Ассортимент косметики по уходу за лицом

-

Ni·Shangle Gallery Unveils Art-Inspired Lifestyle Tips & Trends for 2023

-

The Ultimate Guide to Washable Adhesive Silicon Grips: Innovation, Versatility, and Performance

-

Kexing Medical Device Shines at 2025 Shenzhen International High-Performance Medical Device Exhibition

-

Ассортимент автоматизированных механических деталей