In the realm of precision manufacturing, Original Equipment Manufacturer (OEM) CNC machining stands as a cornerstone technology, delivering unparalleled accuracy, efficiency, and versatility. This advanced manufacturing process has revolutionized various industries, from aerospace to automotive and beyond, by enabling the production of intricate components with tight tolerances.

Precision and Accuracy at Unprecedented Levels

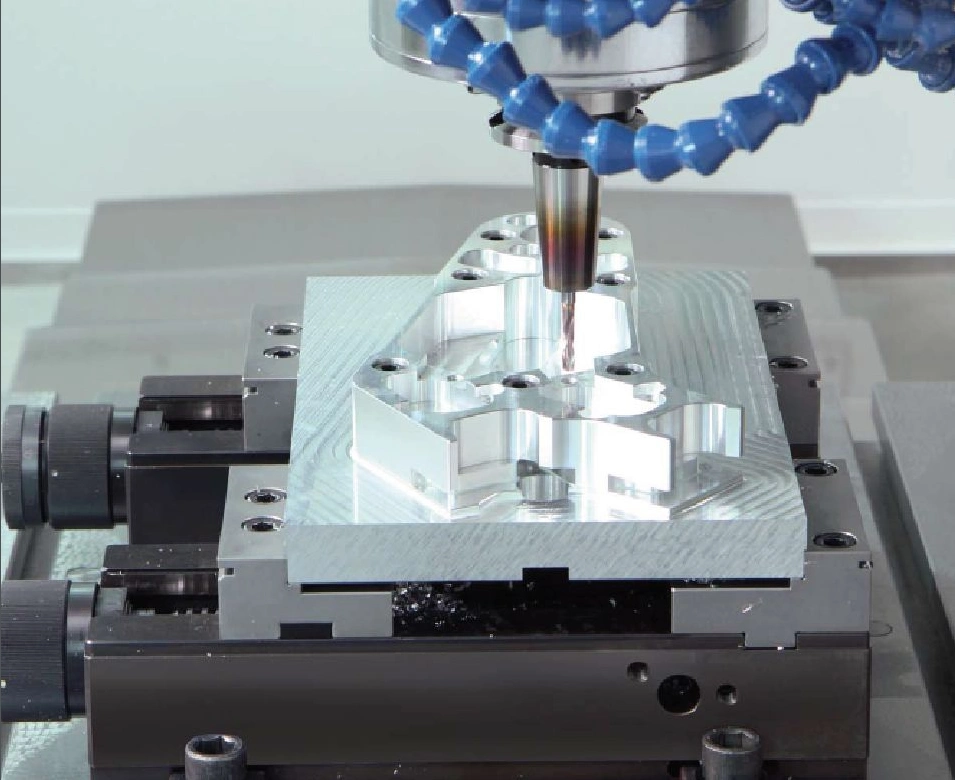

One of the most significant advantages of OEM CNC machining lies in its ability to achieve exceptional precision and accuracy. With computer numerical control (CNC) technology, machines can operate with a high degree of repeatability, ensuring that each part produced meets stringent specifications. This precision is crucial in industries where even the smallest deviation can compromise the functionality or safety of a product.

Changhong Precision leverages state-of-the-art CNC machines equipped with advanced sensors and software, capable of maintaining tolerances as tight as ±0.005mm. This level of accuracy allows them to produce components that fit seamlessly into assemblies, reducing waste and enhancing overall product performance.

Versatility in Design and Material Handling

CNC machining offers immense versatility in terms of design and material handling. From complex geometries to intricate details, CNC machines can carve out almost any shape from a wide range of materials, including metals, plastics, and composites. This flexibility allows manufacturers to innovate freely, bringing new designs to life without the limitations of traditional manufacturing methods.

Changhong Precision boasts a comprehensive portfolio of materials and finishes, enabling them to tailor solutions to specific customer requirements. Their expertise in handling diverse materials, such as aluminum, stainless steel, titanium, and advanced plastics, ensures that clients can achieve the optimal balance of performance, cost, and aesthetics in their final products.

Cost-Effectiveness and Scalability

OEM CNC machining is known for its cost-effectiveness, especially when producing small to medium-sized batches. Unlike mold-based manufacturing methods, which require significant upfront investments, CNC machining allows for quick setup and changeovers, reducing lead times and minimizing costs associated with tooling. Furthermore, as demand grows, the scalability of CNC machines ensures that production can be ramped up without significant disruptions.

Changhong Precision offers a streamlined production process that maximizes efficiency and minimizes waste. Their lean manufacturing practices, combined with advanced CAD/CAM software, ensure that designs are optimized for production, reducing setup time and material consumption. This results in cost savings that are passed onto customers, making high-quality precision parts more accessible.

Short Lead Times and Quick Prototyping

In today's fast-paced market, the ability to quickly bring products from concept to reality is crucial. CNC machining excels in this area, offering short lead times for both prototypes and final products. This rapid turnaround is ideal for industries that need to test and iterate designs frequently, or for those facing tight deadlines.

Changhong Precision excels in rapid prototyping and short-run production. Their team of engineers and machinists work closely with clients to understand their needs, ensuring that prototypes are delivered swiftly and accurately. This capability not only accelerates the product development cycle but also allows for earlier detection and rectification of design flaws, leading to better overall product quality.

Sustainability and Environmental Responsibility

In the era of sustainability, OEM CNC machining also stands out for its environmental benefits. By minimizing material waste, reducing the need for extensive tooling, and utilizing energy-efficient machinery, CNC machining contributes to a more eco-friendly manufacturing process.

Changhong Precision is committed to sustainable practices. They optimize material usage to minimize scraps and recycle whatever waste is generated. Additionally, their machines are equipped with energy-saving features, contributing to lower carbon emissions. This dedication to sustainability aligns with the values of many modern businesses, making Changhong Precision an attractive partner for environmentally conscious clients.

Conclusion

OEM CNC machining in precision manufacturing offers a multitude of benefits, from unparalleled precision and versatility to cost-effectiveness and sustainability. Changhong Precision, with its advanced technology, expertise, and commitment to quality, stands out as a leading provider in this domain. By offering tailored solutions that meet the unique needs of clients across diverse industries, Changhong Precision is driving innovation and value in precision manufacturing, setting a benchmark for excellence in the field.

www.chmetalprecision.com

深圳市长弘精密技术有限公司

About Author

You may also like

-

Ассортимент косметики по уходу за лицом

-

Ni·Shangle Gallery Unveils Art-Inspired Lifestyle Tips & Trends for 2023

-

The Ultimate Guide to Washable Adhesive Silicon Grips: Innovation, Versatility, and Performance

-

Kexing Medical Device Shines at 2025 Shenzhen International High-Performance Medical Device Exhibition

-

Ассортимент автоматизированных механических деталей