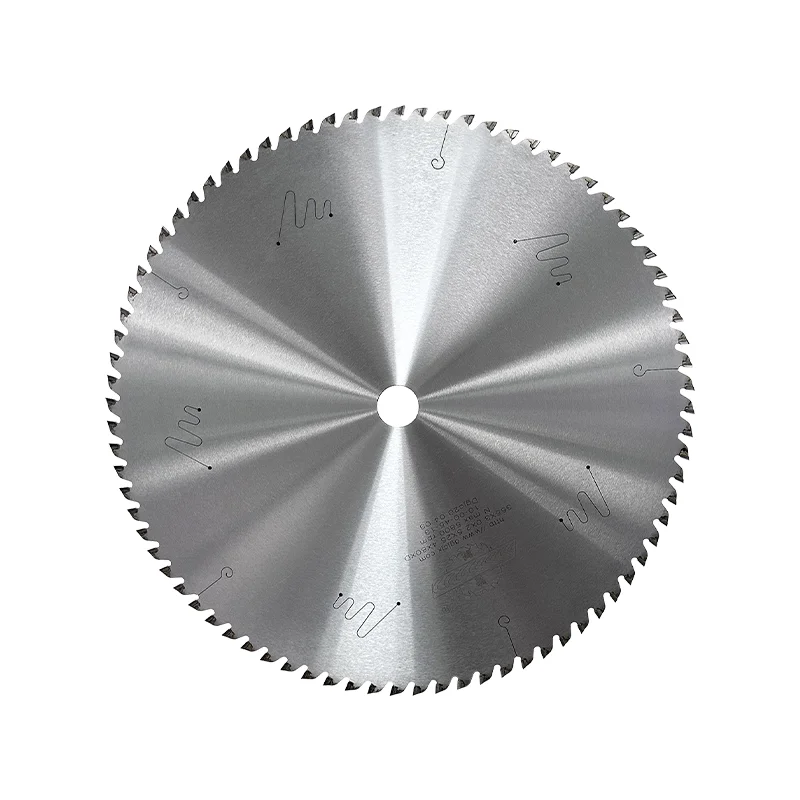

As a high-performance cutting tool widely used in the modern industrial field, tungsten carbide circular saw blades are widely used for high-speed cutting of metal, aluminum, plastic, wood and other materials due to their excellent hardness, wear resistance and cutting efficiency. Compared with ordinary alloy circular saw blades, tungsten carbide circular saw blades have longer service life and higher precision, so they are usually more expensive. So, what are the factors that affect the price of tungsten carbide circular saw blades? This article will analyze in detail from multiple dimensions.

1. Raw material quality is the root of price differences

Tungsten steel, also known as cemented carbide (Tungsten Carbide), is an alloy material sintered from tungsten powder and carbide, with extremely high hardness and wear resistance. The core raw materials of tungsten carbide circular saw blades include:

Tungsten powder purity

The higher the purity of tungsten powder, the more stable the tungsten steel material produced, and the stronger its heat resistance and crack resistance. The price of this high-purity tungsten powder is naturally higher, which directly increases the cost of the entire saw blade.

Binder ratio

Cobalt, as a commonly used bonding metal, not only affects the toughness of cemented carbide, but also affects the impact resistance of the entire saw blade. The price of tungsten steel with high cobalt content is significantly higher than that of low cobalt alloy.

Saw blade base material

In addition to the sawtooth part, the base of the saw blade is usually made of high-strength alloy steel. If high-end imported steel (such as SKS5, 75Cr1, etc.) is used, its thermal deformation coefficient is low and the price is higher.

2. Design complexity of saw blade tooth type and number of teeth

The tooth type design and tooth number density of tungsten carbide circular saw blade directly affect its processing performance and indirectly affect the cost:

Tooth type design complexity

Different materials have different requirements for cutting tooth types. For example, negative rake angle stepped flat teeth (TP) are required for cutting aluminum profiles, and high rake angle teeth are required for plastic materials. The higher the design complexity of the tooth type, the higher the processing difficulty and precision requirements, and the price naturally rises.

The more teeth, the more expensive the price

The more teeth, the smoother the cutting and the finer the incision per unit time, but the manufacturing cost also increases. Some high-end precision saw blades are often equipped with 80 teeth, 100 teeth or more, and the price is much higher than the conventional 40 teeth and 60 teeth products.

3. The advanced degree of manufacturing process determines the quality difference

Welding process

The quality of the connection between the tooth and the substrate depends on the quality of the brazing process. At present, the mainstream of the industry is high-frequency brazing and laser welding, among which laser welding technology is more advanced, which can effectively reduce the problem of tooth stripping and tooth loss, and the cost is also higher.

Precision tooth grinding

High-end tungsten carbide circular saw blades must undergo multiple CNC tooth grinding processes to ensure that the front angle, back angle, side angle and tooth height of each tooth are uniform and accurate. This type of processing uses high-precision five-axis grinding equipment, which has high investment costs, and the price of the saw blade is naturally higher.

Surface coating treatment

Some tungsten carbide circular saw blades use TiN (titanium nitride), TiAlN (titanium aluminum nitride), DLC (diamond-like carbon) and other coatings to improve their wear resistance and heat resistance. High-quality coating technology is one of the important factors for price increases.

4. Customized demand will affect the unit price

Many end customers will put forward personalized requirements based on specific application scenarios, such as customized tooth shape, non-standard diameter, enhanced thickness, silent design, etc. These requirements usually significantly increase the unit price of saw blades. For example:

Silent design: adding silencer grooves, copper nails or damping resin layers to the surface of the saw blade increases the manufacturing cost by 10%-30%;

Non-standard size saw blades: need to be programmed separately, molded, and tool paths adjusted, and the unit cost is much higher than that of batch standard parts;

Multi-blade saw customization: need to consider special designs such as assembly errors and cooling slot structures, and the price is higher.

5. Purchase quantity and supply channel affect the purchase unit price

Bulk purchase is more cost-effective

Under the same quality standard, the larger the single purchase volume, the greater the discount given by the supplier.

Distributor vs. factory direct supply

Purchasing through brand distributors often comes with channel profits, while purchasing directly from saw blade manufacturers can eliminate intermediate costs and be more cost-effective.

6. Whether there are additional services and after-sales support

Some high-end tungsten carbide circular saw blade suppliers not only provide products, but also include supporting:

Use training and operation guidance;

Saw blade grinding and refurbishment services;

On-site application testing services;

Cutting scheme optimization suggestions;

Although this type of "product + service" model increases the overall price, it greatly reduces the risk of use, and the cost-effectiveness is higher.

There are many factors that affect the price of tungsten carbide circular saw blades, from raw materials to manufacturing processes, from brands to personalized services, and each link may cause price fluctuations. For buyers, instead of blindly pursuing low-priced products, it is better to evaluate the cost-effectiveness of saw blades from a comprehensive perspective such as service life, cutting stability, and service support.

If you need to wholesale or customize high-performance tungsten carbide circular saw blades, it is recommended to choose a professional manufacturer with technical strength, stable production capacity, and full-process services to ensure long-term stable operation of the product and reduce later losses and maintenance costs.

If you need to obtain tungsten carbide circular saw blade selection suggestions or bulk quotations, please contact our professional engineer team, and we will provide you with customized solutions and technical support.

www.chinechernmachine.com

DongGuan Chine Chern Machinery Co.,Ltd.

About Author

You may also like

-

How to Select the Right Vacuum Suction Unit for Chemical Applications in Industrial Projects

-

How to Choose an ISO Certified Automotive Starter Manufacturer for Reliable Bulk Supply

-

How to Select the Right Vacuum Suction Unit for Chemical Applications in Industrial Projects

-

What Buyers Should Know Before Ordering Custom FR4 Fiberglass Boards

-

How 35kV Epoxy Resin Transformers Help Buyers Achieve Reliable and Safe Power Distribution