In the demanding world of steel and metal production, efficiency is everything. Whether it's reducing energy consumption, shortening production cycles, or improving product quality, manufacturers are constantly seeking ways to optimize their operations. One of the most impactful factors in achieving this is the implementation of advanced metallurgical machinery.

In this article, we explore how metallurgical machinery enhances productivity and efficiency in modern metal industries — and how leading suppliers like China Special Metal Group Limited (CSM) play a crucial role by delivering high-quality cast steel components and precision-engineered products for metallurgical applications.

What Is Metallurgical Machinery?

Metallurgical machinery encompasses a wide range of equipment used throughout the steel and non-ferrous metal production process. These machines are essential in:

-

Ore handling and preparation

-

Melting and refining

-

Casting and shaping

-

Rolling and finishing processes

Common examples include ladle turrets, rolling mill stands, converter hoods, slag pots, and segment assemblies.

Key Ways Metallurgical Machinery Boosts Efficiency

1. Streamlining Production Processes

Modern metallurgical machines are designed to automate and accelerate various stages of production. Automated handling systems and casting equipment reduce human error and speed up throughput.

2. Improving Precision and Quality

High-precision machinery ensures that metal products meet strict dimensional tolerances, which is vital for high-performance applications in automotive, aerospace, and construction sectors.

3. Enhancing Equipment Lifespan

Using durable cast steel components reduces wear and downtime. When machines last longer and require less maintenance, overall efficiency improves significantly.

4. Energy Optimization

Modern metallurgical equipment is designed to consume less energy during melting, rolling, and refining operations — contributing to lower operational costs and a reduced environmental footprint.

5. Better Integration with Digital Technologies

Many new-generation machines are compatible with IoT and AI-based monitoring systems, enabling predictive maintenance and real-time process optimization.

CSM: Your Trusted Partner in High-Performance Metallurgical Components

China Special Metal Group Limited (CSM) is a globally recognized supplier of cast steel products and precision components for industries such as metallurgy, cement, ceramics, shipbuilding, mining, and chemicals.

For the metallurgical sector, CSM provides:

-

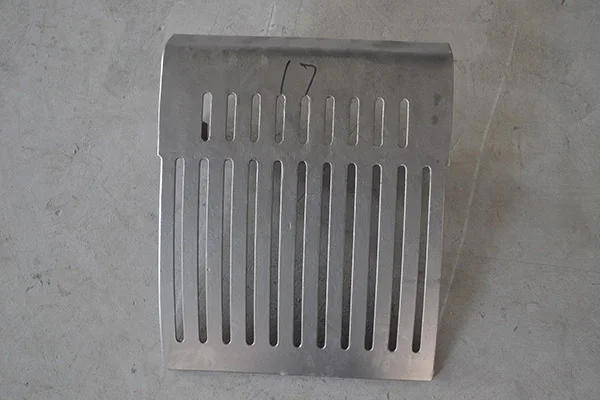

High-quality cast steel parts like slag pots, ladle car frames, and rolling mill housings

-

Custom-machined components with high dimensional accuracy

-

Welded steel structures and assemblies built to customer specifications

With strong production capacity, advanced foundry technology, and strict quality control processes, CSM supports steel manufacturers in upgrading their machinery and achieving higher productivity.

Applications in Steel and Metal Production

CSM’s metallurgical products are widely used in:

-

Blast furnaces and steel converters

-

Continuous casting machines

-

Rolling mills for plates, bars, and coils

-

Auxiliary systems like crane components and cooling beds

Each component is designed to withstand high temperatures, mechanical stress, and harsh operating conditions, ensuring stable and efficient production.

Conclusion

As global demand for high-quality steel and metal products continues to rise, investing in advanced metallurgical machinery becomes essential for manufacturers seeking greater efficiency and competitiveness. High-performance components from trusted suppliers like China Special Metal Group Limited (CSM) make a significant difference in operational reliability and cost-effectiveness.

Looking to enhance your steel or metal production line? Contact China Special Metal Group Limited (CSM) today to explore customized cast steel solutions built for industrial efficiency.

www.special-metal.com

Shanghai Special Metal Co.,Ltd

About Author

You may also like

-

How to Select the Right Vacuum Suction Unit for Chemical Applications in Industrial Projects

-

How to Choose an ISO Certified Automotive Starter Manufacturer for Reliable Bulk Supply

-

How to Select the Right Vacuum Suction Unit for Chemical Applications in Industrial Projects

-

What Buyers Should Know Before Ordering Custom FR4 Fiberglass Boards

-

How 35kV Epoxy Resin Transformers Help Buyers Achieve Reliable and Safe Power Distribution