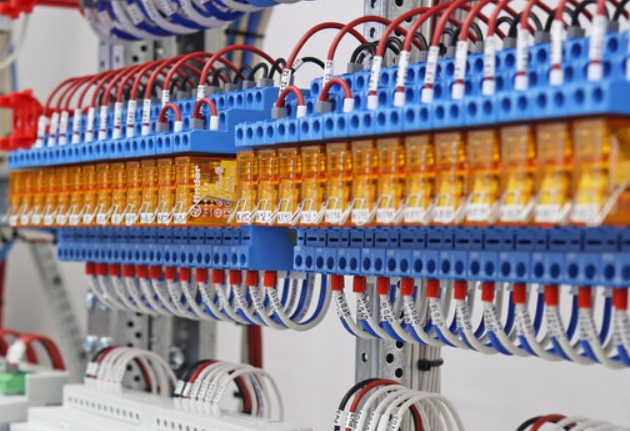

Relays play a crucial role in various industries, enabling the control and protection of electrical circuits. From power distribution to telecommunications, relays ensure the smooth operation of complex systems. In this blog post, we will delve into the essential requirements of a relay, exploring the key elements that contribute to its reliability and efficiency.

- Contact Materials:

The choice of contact materials is paramount in determining the performance and longevity of a relay. High-quality materials such as silver, gold, or palladium-based alloys are commonly used due to their excellent conductivity, low resistance, and resistance to corrosion. These materials ensure reliable electrical connections and minimize contact wear, enhancing the overall reliability of the relay. - Coil Design and Construction:

The coil is the heart of a relay, responsible for activating the contacts. To meet the demands of different applications, the coil design should consider factors such as voltage, current, and response time. Additionally, the coil's construction should minimize electromagnetic interference, ensuring stable and accurate operation even in challenging environments. - Contact Arrangement:

Relays can have various contact arrangements, including normally open (NO), normally closed (NC), and changeover (CO) contacts. The selection of the appropriate contact arrangement depends on the specific application requirements. A well-designed contact arrangement ensures seamless switching between circuits, minimizing signal loss and maintaining system integrity. - Insulation and Sealing:

Relays often operate in harsh environments, exposed to temperature variations, moisture, and contaminants. Adequate insulation and sealing are essential to protect the internal components from external factors. High-quality insulation materials, such as ceramics or polymers, provide electrical and thermal insulation, while effective sealing prevents the ingress of dust, moisture, and other contaminants. - Overload and Surge Protection:

Relays must withstand overloads and surges without compromising their functionality. Incorporating protective features such as overload relays, surge suppressors, and transient voltage suppression diodes enhances the relay's ability to handle unexpected electrical disturbances. These protective measures safeguard the relay and the connected equipment, ensuring reliable and uninterrupted operation.

Conclusion:

Relays are indispensable components in numerous industries, enabling the control and protection of electrical circuits. By understanding the essential requirements of a relay, including contact materials, coil design, contact arrangement, insulation, and protective features, engineers and technicians can select and deploy reliable relay systems that meet the demands of their applications. Investing in high-quality relays not only ensures the smooth operation of systems but also contributes to overall safety and efficiency.

About Author

You may also like

-

Maximizing Survey Accuracy with Advanced Surveying BeiDou Modules

-

What is fiber splice enclosure?

-

Inside the ARKON 2.4G Wireless Headphone DHP380A

-

High-Precision Drone GNSS Modules: Solutions for Efficient UAV Operations

-

Reducing Heat and Energy Loss in EV Powertrains with Laminated Bus Bar Technology